Sheet Metal Pressing Company in Chennai

Sheet Metal Pressing Company in Chennai

We are a stupendous company in Chennai in the field of Sheet Metal Pressing. For any questions contact us.

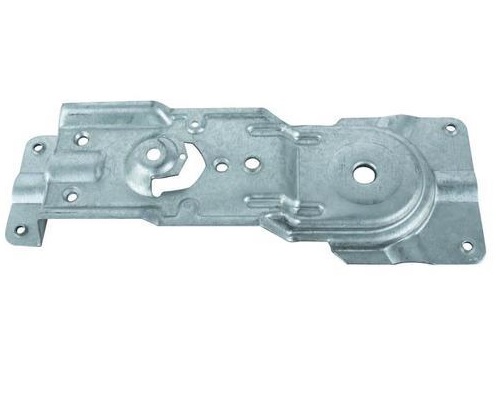

Sheet Metal Pressing involves placing flat sheet metal, in moreover coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the required shape. Punching, bending, coining, flanging, and embossing blanking, are all stamping techniques used to shape the metal.

Types of Sheet Metal Pressing

Manually Operated Press

The press is operated by human hands. It is a bench-mounted press regularly used for the production of small components. It is a trouble-free and low-cost press, suitable for light operations, like, bending, piercing, blanking, etc.

Electric Motor Operated Press

The press is operated by an electric motor. The motor drives the eccentric shaft which converts the rotational motion into reciprocating motion of the ram. The ram fitted with the punch, to run upon the job held on the die block and bolster.

Hydraulic Press

The hydraulic press uses the oil or water pressure to move the slide and ram up and down. A Pump is working to supply the liquid under high pressure to the cylinder. Hydraulic presses are available in capacities up to 15000 tons. Therefore, these presses are specially employed for extruding, piercing, drawing, and blanking metals above 3mm thickness.

Inclinable Press

- Work part can automatically slide by gravity into the container box.

- Scrap release from the work piece is automatic.

- It can be used for perpendicular as well as any inclined position.

- These presses are used in the production of small parts involving blanking, bending, and punching operations.

Straight-Side Press

It has a high capacity for work. It has an inflexible frame and is used in mechanical and hydraulic presses where heavy loads are produced. These kinds of presses are used for forming heavy and, deep drawing, thick metals, coming, etc.

How are Pressing Produced?

Pressing is created by inserting flat sheet metal into a specialist machine often referred to as a stamping press, but also occasionally called a power press. This metal is then shaped into the correct forms through the use of a metal die.

Blanking: The method by which a flat shape is cut out of the material, this process usually leads to further processing.

Embossing: A shallow depression is forced into the material.

Bending: The material is shaped in one direction. This can occur multiple times to produce a particular shape.

Coining: Named after the item it was primarily used to create, coining is the method by which a pattern is compressed into the flat sheet metal.

Visit us in Google Maps

FAQS

What is a press used for?

This large class of machines includes tools used for forming metal parts by applying the following processes: shearing, blanking, forming, flanging, squeezing, drawing, bending, forging, coining, upsetting, and hammering.

What is the Sheet metal pressing process?

Sheet Metal presswork sometimes referred to as metal pressing or metal stamping is the method of forming a shape from a metal sheet, coil, or tube, using a press tool and stamping dies. The metal is manipulated to the shape of the die to produce precise and perfect components.

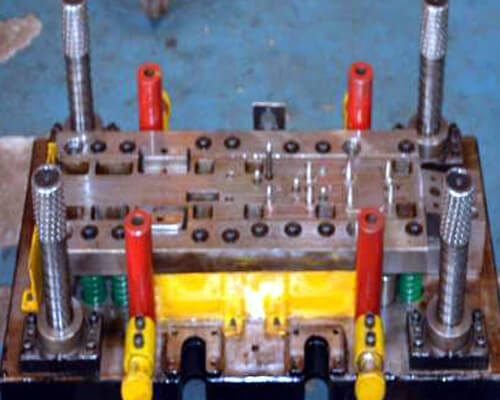

How is sheet metal dies made?

Forming operations work by deforming materials like sheet metal or plastic using force and swear on the material’s mechanical properties. Forming dies are normally made by tool and die makers and put into production after mounting into a press.

Our Related Product:

Fixture Manufacturers in Chennai

Press Metal Manufacturers in Chennai

Press Metal Manufacturers in Tamilnadu

Press Tools Manufacturers in Chennai

Sheet Metal Manufacturers in Chennai

Sheet Metal Manufacturers in Tamilnadu

Sheet Metal Pressing Company in Chennai

Sheet Metal Stamping Company in Chennai