Press Tools Manufacturers in Chennai

Press Tools Manufacturers in Chennai

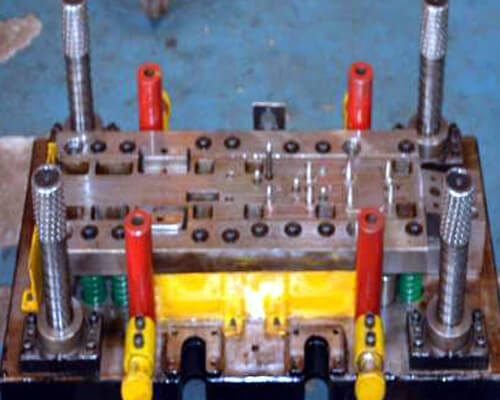

Press Tools Manufacturers in Chennai offered by Jai Sai Toolings is one of the trustworthy names in the industry with a team of experts.

Press tools are frequently used in hydraulic, pneumatic, and mechanical presses to produce components at high volumes. In general, press tools are characterized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming, etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool, etc.

Advantages of using Press Tool

- One of the main advantages of using the presswork method is that it is suitable for an extensive range of different applications. Certainly, the presswork method is incredibly versatile.

- Power presses come in a mixture of forms and have evolved over many years of development. Generally presses are still mechanical which provides a single blow of defined tonnage and stroke.

- The pressing method also provides a high level of strength for parts that are relatively thin. Again, it guarantees that it is probable to deliver a high quality element that clients want and expect. This doesn’t change based on the presswork machine you choose.

- This method can also be completed at a reasonable price. Although high energy consumption press work is often a reasonable solution and will fit the finances of numerous businesses.

Types of Press Tool

Blanking Press Tool

A blanking tool can cut off the outer profile of a metal sheet. It can cut it in its whole with one single stroke, using one punch and die. This is used to cut a flat shape out of a metal sheet.

Compound Press Tool

While utilizing the compound tool, the blanking and intense stages are fused into one by inverting the tool itself. There is no piercing die needed.

Combination Press Tool

Combination tools can concurrently perform two operations. It combines one operation, like forming, with a cutting operation, such as blanking off. Mostly, a cutting and non-cutting operation is performed together, but not two cutting operations.

Cut Off Press Tool

Similar to the name sounds, a cut-off tool shears off a strip of sheet metal. The process is one single motion, and the user determines what size strip dimension to cut.

Drawing Press Tool

The drawing tool takes a smooth sheet of metal and shapes it into forms like cups and shells. This method is called elastic or plastic deformation.

Forming Press Tool

Related to the binding tool, a forming tool can apply more complicated bends to stampings that curve.

Visit us in Google Maps

FAQS

What are press tool operations?

Press tools usually perform some type of task within a hydraulic, pneumatic, or mechanical press machine to produce metal components in large quantities. Different press tools perform various tasks, such as piercing, blanking, forming, bending, trimming, or forging.

What is part of the press tool?

The press tool consists of Punches, Die, Punch Plate, Backup plate, Stripper, Ejectors many more components. To better understand the main components of the press and dies.

Can stainless steel be press-formed?

This is the forming operation whereby a flat sheet is pressed into cylindrical and rectangular shapes by means of a punch and die set up. Mechanical and hydraulic presses in regular use can be used for stainless steel drawing operations, but again the capability is extensively reduced.

Our Related Product:

Fixture Manufacturers in Chennai

Press Metal Manufacturers in Chennai

Press Metal Manufacturers in Tamilnadu

Press Tools Manufacturers in Chennai

Sheet Metal Manufacturers in Chennai

Sheet Metal Manufacturers in Tamilnadu

Sheet Metal Pressing Company in Chennai

Sheet Metal Stamping Company in Chennai

Leave a Reply

Want to join the discussion?Feel free to contribute!